Elevator Rotary Encoder Price and Quantity

- 1 Piece

- 5800 INR/Piece

Elevator Rotary Encoder Specification

- Stainless Steel

Elevator Rotary Encoder Trade Information

- 5 Piece Per Day

- 1-7 Days

Product Description

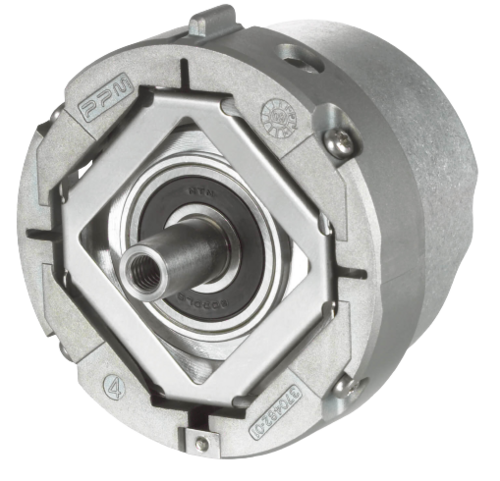

A rotary encoder with regards to elevators is a gadget used to quantify the position and bearing of turn of an elevators moving parts, regularly the elevator vehicle or the elevator's entryways. It gives exact criticism to the elevator control framework, empowering it to precisely control the elevator's development and guarantee wellbeing and productivity.

FAQs of Elevator Rotary Encoder:

Q1: What is an elevator rotary encoder, and what is its essential capability?

A1: An elevator rotary encoder is a sensor that changes over the rotational development of an elevator part (like the elevator vehicle or entryways) into electrical signs. Its essential capability is to give input on the position, speed, and course of the elevator's moving parts to the elevator control framework.

Q2: How does an elevator rotary encoder work?

A2: A rotary encoder commonly comprises of a pivoting circle or shaft and sensors that identify the turn. As the elevator part (e.g., vehicle or entryways) moves, the encoder measures the turn and conveys electrical messages, like heartbeats or advanced signals, to the control framework. The control framework deciphers these signs to decide the position and development of the part.

Q3: What are the principal parts of an elevator rotary encoder?

A3: The principal parts of an elevator rotary encoder incorporate the pivoting circle or shaft, sensors (generally optical or attractive), and gadgets to process and send the sign.

Q4: For what reason are rotary encoders significant in elevators?

A4: Rotary encoders are basic in elevators since they give exact criticism on the position and development of key parts. This data permits the elevator control framework to work the elevator securely and proficiently, guaranteeing that it stops at the right floor and that entryways open and close without a hitch.

Q5: What sorts of data do elevator rotary encoders give to the control framework?

A5: Elevator rotary encoders give data like the place of the elevator vehicle inside the shaft, the place of the entryways (open or shut), and the speed and bearing of development. This information is pivotal for precise control and security.

Q6: Are elevator rotary encoders utilized in both footing and pressure driven elevators?

A6: Indeed, elevator rotary encoders are utilized in different kinds of elevators, including footing elevators (which use links) and water powered elevators (which utilize pressure driven frameworks). The sort and utilization of the encoder may change relying upon the elevator plan.

Q7: Might elevator rotary encoders at any point fizzle, and how are they kept up with?

A7: Like any mechanical or electronic part, elevator rotary encoders can bomb over the long run because of mileage or electrical issues. Normal upkeep and investigations are fundamental to guarantee their legitimate working. If an encoder fizzles, it ought to be supplanted speedily to keep away from elevator breakdowns.

Q8: Might rotary encoders at any point be incorporated with elevator modernization or control framework overhauls?

A8: Indeed, elevator modernization projects frequently incorporate moves up to the control framework, and this might include supplanting or redesigning rotary encoders to improve elevator execution, security, and energy productivity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Call Me Free

Call Me Free