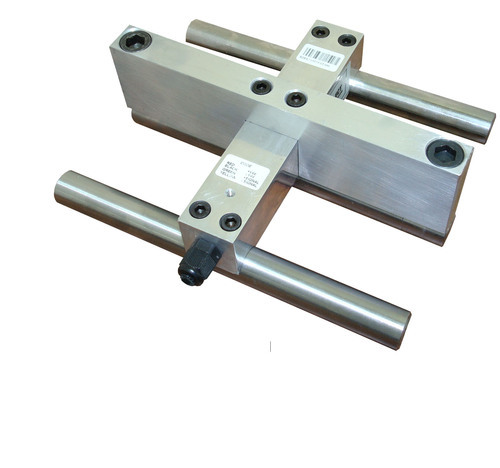

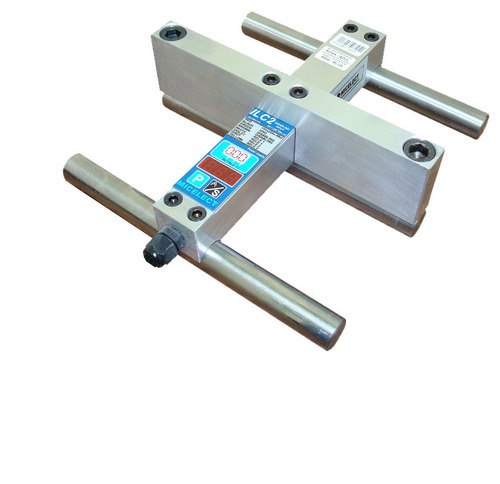

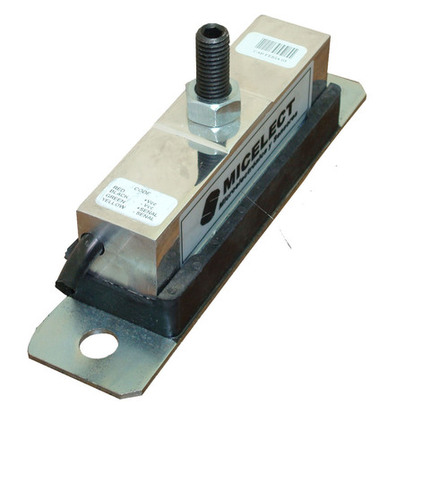

Hydraulic Sensor

Product Details:

Hydraulic Sensor Price and Quantity

- 11500 INR/Piece

- 1 Piece

Hydraulic Sensor Trade Information

- 5 Piece Per Day

- 1-7 Days

Product Description

A hydraulic sensor, otherwise called a tension sensor or hydraulic strain sensor, is a gadget intended to gauge the strain of a hydraulic liquid inside a hydraulic framework. Hydraulic frameworks are normally utilized in different modern and mechanical applications, like in large equipment, car stopping mechanisms, aviation, and then some. Observing and controlling hydraulic strain is essential for guaranteeing the appropriate activity and security of these frameworks.

FAQs of Hydraulic Sensor:

Q1: What is a hydraulic sensor?

A1: A hydraulic sensor is a gadget intended to gauge the tension of hydraulic liquids inside a hydraulic framework. It gives important data about the strain levels in the framework.

Q2: For what reason are hydraulic sensors significant?

A2: Hydraulic sensors are vital for keeping up with the protected and productive activity of hydraulic frameworks. They assist with forestalling overpressure, screen framework wellbeing, and give information to control and input inspirations.

Q3: What sorts of hydraulic sensors are accessible?

A3: There are different kinds of hydraulic sensors, including pressure sensors, pressure transducers, and strain switches. These sensors are utilized to quantify and screen the strain of hydraulic liquids.

Q4: How do hydraulic sensors work?

A4: Hydraulic sensors commonly work by utilizing a stomach or a strain measure to distinguish changes in hydraulic tension. At the point when strain is applied, these parts distort, and this misshapening is changed over into an electrical sign, which can be estimated and deciphered.

Q5: What are the normal utilizations of hydraulic sensors?

A5: Hydraulic sensors are utilized in a large number of utilizations, including hydraulic chambers, hydraulic siphons, hydraulic power units, and hydraulic control frameworks. They are fundamental in applications where exact tension control and checking are vital.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry